News Details

2019-03-19

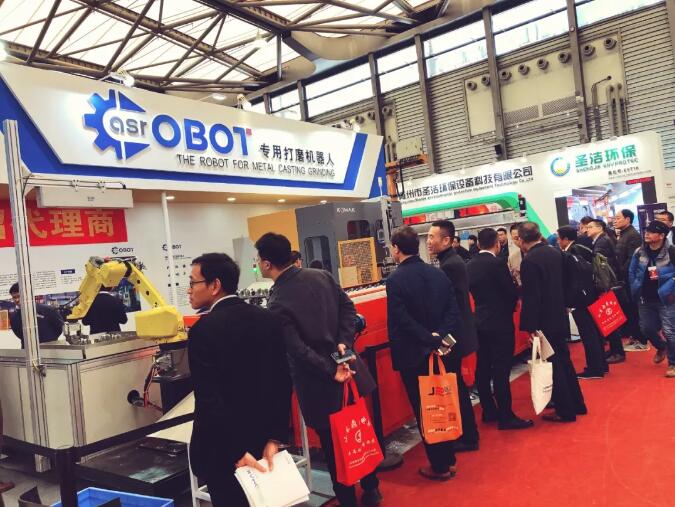

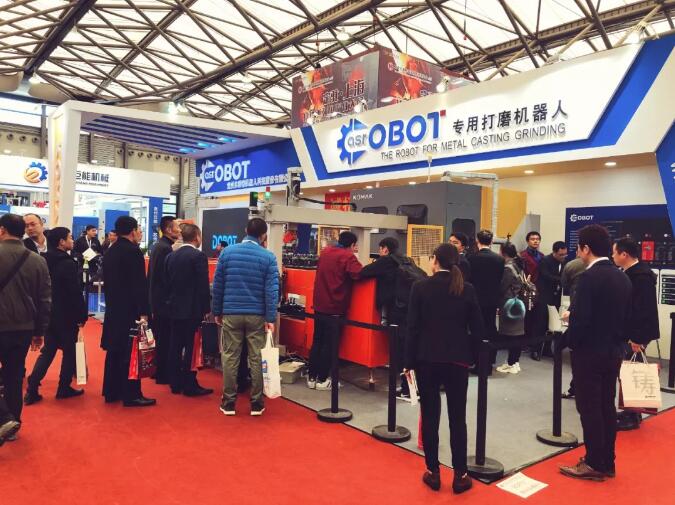

On March 16, 2019, the 17th China International Foundry Expo, sponsored by China Foundry Association, ended successfully at Shanghai New International Expo Center.

China International Foundry Expo was founded in 1987, after 30 years of accumulation and innovation has grown into a world-renowned foundry expo, exhibitors and visitors from China, Germany, the United States, Russia, Japan and other more than 80 countries and regions, for the pulse industry, communication, cooperation to create a good opportunity.

In this exhibition, the KOMAK automatic grinding robot independently developed by Changzhou Dobot Robot Technology Co., LTD., a subsidiary of DAS Group, and the automated production line supporting the machine appeared at the E5-T17 booth. Once exhibited, it attracted many industry customers at home and abroad.

KOMAK grinding robot

KOMAK series casting grinding robot is specially developed and manufactured by DoBOT for casting customers to solve the industry problems of surface grinding of irregular curved castings. The whole machine is fully independent research and development, from the core robot brain multi-axis motion control algorithm, grinding process, mechanical design to intelligent fixture design, deep process cognition for casting grinding, more than ten domestic independent research and development of patent inventions, all reflect the strong technical advantages of KOMAK robot. It has become the first fully independent robot in China, and all accessories are produced domestically, thereby reducing equipment costs. It is used to replace the labor force of casting grinding workers, improve production efficiency, reduce production costs, and lay a good foundation for the future unmanned automated production factory.

KOMAK casting special grinding robot is used to polish and remove all kinds of casting spout, flash, and inner and outer burrs, equipped with fully independent design and development of special control system, easy to operate, fast and upgrade, easy to maintain. Is a set of intelligent, efficient, environmental protection in one of the high-tech products.

KOMAK automated production line

The machine equipped with automated production line can basically achieve fully automatic unattended operation, freeing the labor force, and can be matched with DAS intelligent cloud information platform to realize the production workshop PC, mobile phone and other mobile terminal monitoring, intelligent customization module can push the factory emergency to the manager's wechat terminal in time.

This automatic production line is composed of loading transmission system (double round trip), truss manipulator transfer system, and blanking transmission belt. Automatic sorting through machine vision greatly reduces manual duty time, and can flexibly support multi-axis truss manipulator to grasp multiple workpieces. High fault tolerance of the feeding system and accurate positioning of the truss manipulator.

The four-day exhibition came to a successful end! Dobot will continue to forge ahead, and will return to you with more high-quality and diverse products and better services in the future, please look forward to it!